Maurits van de Water (Van de Water Fruit Group) on Burg MachineFabriek installations

“Water purification systems are always a good investment for more than ten channels”

Tholen – The busiest weeks of the year have arrived at Van de Water Fruit Group in Waalwijk for sorting Sweet Sensation pears. The fruit is sorted on a 2x four-lane machine from Perfect with Ellips hardware and software, which can sort two varieties simultaneously. The sorting company has a Burg 3D portal for the supply with fifteen water channels that will soon be dynamically controlled. In addition to the water dumper, the fruit company also invested in two Burg water purification systems in 2018, both a lamella filter at the inlet of the field crop and a sand filter with UV light on the less contaminated side of the line at the pre-sorting stage. This machine purifies the water channels and the small pack machine.

The BWZ-15 uses a sand/glass filter for fine filtration.

For Maurits van de Water, the choice for a water purification system was a no-brainer. “During construction, I walked through the hall and saw what we had to clean here every week; with fifteen water channels, that was simply not feasible. That’s why we investigated the possibilities of water purification, and Burg came up with this proposal.” Although he also investigated the possibilities of water purification abroad with suppliers, he ended up choosing the supplier from Kruiningen in Zeeland. “And I am very happy that I bought everything in the Netherlands. In the event of malfunctions and maintenance, it is very pleasant to be able to explain what is going on in your own language. What’s more, technicians are always within reasonable distance to provide high-quality service.”

The BLS-6 (lamella filter) works by means of pre-filtering with a flocculant dosage and has a lamella package of 6 cubic meters per hour. Both filters have a UV disinfection system.

The water treatment plant has now been in operation for almost three years and, according to Maurits, it is working satisfactorily. “If I had to make the choice again, I would do it in a heartbeat. It’s not as if the water treatment plant requires no attention after installation and runs immediately after installation. It’s a process you have to work on every day, but after an initial start-up phase, the entire installation is now running smoothly. In terms of maintenance and cleaning, this water treatment system saves me 16 hours of work per week. But activities such as cleaning the filters must be kept up to date to keep everything in good working order. In addition, major maintenance is carried out on the system once or twice a year.”

The BWZ-15 contains a carbon filter, UV lamps to reduce bacterial growth, and a dose of hydrogen peroxide.

“There are several aspects that ensure that purification, cleaning, and energy management run smoothly. For example, each type of water reacts differently to purification, and it also makes quite a difference which products go through the line. When we fill the channels prior to the new season, the water appears less clean than it does a week later. It goes in yellow, so to speak, and after a week it is clear. By purifying the water, the machines and products remain cleaner, and we also contribute to less water pollution and waste.”

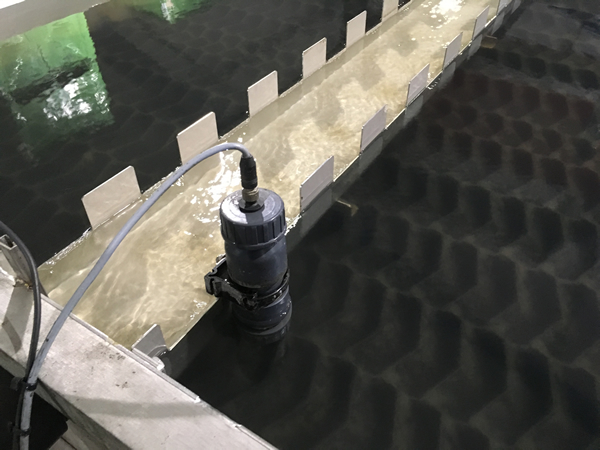

The photo shows the clean water return and turbidity meter.

“I can therefore recommend the installation to everyone. I have advised many fellow packing stations to invest in this, but for some the investment is still too great. Nevertheless, I think that for companies with more than ten water channels, it always pays off. If I had to make the choice again, I would do it again in a heartbeat,” says Maurits. He also has a wish list for the future. “Software programs for these types of machines also require a different level of control. This applies across the board, including for flushing the water channels. Don’t underestimate how much energy those water pumps consume every day.”

Water channels during pre-sorting.

At Burg, they are seeing increasing demand for water treatment plants. “This demand is very broad and comes from Australia, Germany, and England. At Van de Water, the combination of apples and pears is unique. Water treatment for apples is much simpler, whereas with pears there is a greater risk of sugars entering the water, which can block the process. Fortunately, we have gained a lot of experience with this over the past fifteen years,“ says Joan van Burg, who expects that more and more packing stations and cooperatives will invest in water purification. ”When you remove dirt (soil) from water, you also remove chemicals. The peroxide process and the UV module inhibit bacterial growth. In short, it saves work, provides a cleaner working environment, and results in a better end product!”

Clean water return to the infeed.

For more information:

Van de Water fruit Group

Locatie Waalwijk

Overstortweg 9

5145 PT Waalwijk

M +31 (0) 651 890327

maurits@waterfruit.nl

www.waterfruit.nl

Joan van Burg

Burg Machinefabriek

Weihoek 11

4416 PX Kruiningen

Telefoon +31-(0)113-501373

Fax +31-(0)113-502108

jvanburg@burgmachinery.com

www.burgmachinefabriek.nl

Publication date:

Auteur: Izak Heijboer

© AGF.nl