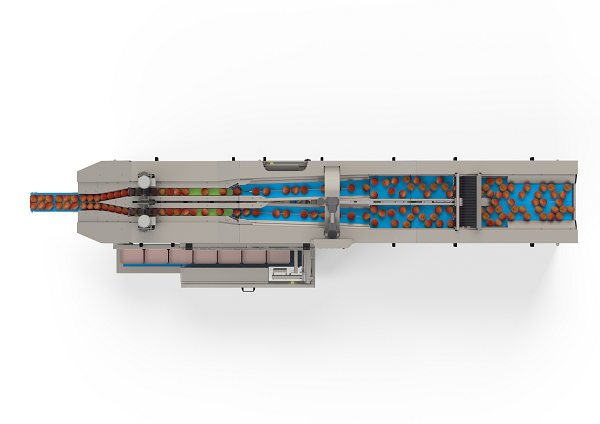

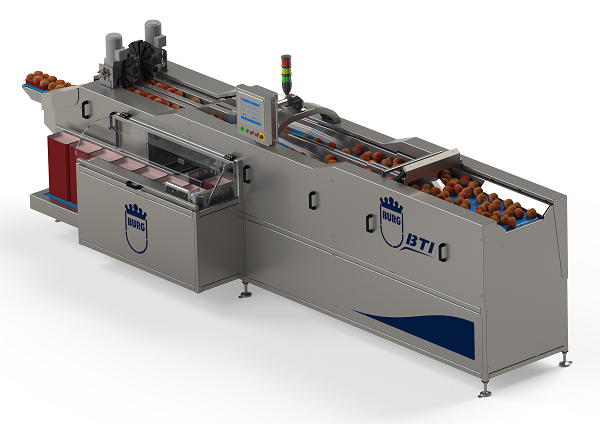

The current trend toward ever-less packaging material is creating more work, not only for packaging designers but also for machine manufacturers. The Dutch company, Burg Machinery, has developed a tray filler for the apple sector. It can process winged cardboard trays too.

“This machine evolved from an earlier model we’d developed for the English market,” says René Koster. “Tesco has one of these lines. It packs sets of loose apples in a flow pack. We then received a request for a solution to flow pack apples in trays.”

“Right away, we improved the machine’s functionality by adding winged cardboard trays to the range of automatic packaging options. That’s unique to our industry. You no longer need plastic to retain the apples in winged trays. You fold the flaps closed and attach a label with the necessary information, and the fruit remains firmly in the packaging. We’ve already sold nine of our BTI tray fillers.”

Two kinds of apples in one tray

This tray filler is fast – it can pack up to 65 trays per minute with 4, 6, or 8 apples. “Other machines can do around 40. Our machine uses two tracks. So, by slightly adjusting its supply side, you can, if you want, feed two different varieties into it. Then a tray of four apples could have two different types. You can use the line for tomatoes too. The machine’s suitable for round products with a 50-90mm diameter and packaging formats with 140-300mm L, 140-180mm W, 20-40mm H dimensions,″ says René.

Same capacity for winged trays

An operator puts stacks of cardboard, plastic, or winged trays into the machine. It automatically de-nests these and places them on a conveyor belt. The machine has the same capacity for both regular and winged trays. After automatically filling the containers, two employees place the apples straight into the crates.

These two, the operator – who places the stacks of trays and operates the machine using a PLC control system – and a forklift driver who fills and empties the crates, are the only staff needed to process more than 60 trays per minute. Upstream (case emptying) and downstream (folding the wing trays, case packing, and palletizing) can be further automated. “You could connect this machine to any supply line and any brand of flowpacker or winged tray folding system.″

Quick return on investment

The fruit hardly touches the machine, despite its speed. “The apples aren’t bruised. The BTI tray filler also pays for itself quickly. If it runs for entire days, a small packer can have written off this investment within 18 months,″ concludes René.

René Koster

r.koster@burgmachinery.com

Burg’s Machinery

Weihoek 11

4416 PX Kruiningen

Nederland

T: +31 113 50 13 73

F: +31 113 50 21 08

info@burgmachinery.com

www.burgmachinery.com

Publication date:

Author: Pieter Boekhout

© FreshPlaza.com